Dynamic seals are used in many areas of robotics, including motors, actuators, and end effectors. But one of the most critical applications is in the robotic arm, which typically performs repetitive tasks in assembly, packaging, and other industrial operations. In most robotic platforms, the arm gets the work done, and it’s often subject to more movement and wear than any other part of the robot. Seals and other robotic arm components are employed at points on the arm where one section is connected to another, at the “joints.”

Not Your Typical Robotic Arm Component

The main difference between seals and other robotic arm components is that seal design requires a delicate balancing act between friction and sealing effectiveness.

The seal must guard against leakage and protect internal mechanisms and electronics from the ingress of dust, moisture, detergents, and other contaminants. However, it must also minimize stick-slip and support consistent positioning over thousands of cycles. This is because, depending on their function, robots may be expected to move with a very high degree of precision – acceptable variances can be as little as +/- 0.02 mm.

The Friction Factor

In any robotic arm component, friction can cause unwanted wear and tear, leading to eventual breakdown. This especially true of seals.

Here are some of the challenges friction can pose in robotic sealing:

- Impedes consistent & accurate movement

- Impacts feedback response of other system components

- Influenced by temperature, pressure and hardware surface finish

- Decreases equipment life by promoting early seal wear

Robotic Sealing Conditions

When designing or selecting a seal for your robot, it’s important to consider the environment in which it’s expected to function.

Here are a few of the most common conditions under which industrial robots work:

- Demanding production environments such as automotive, electronics, agricultural, food & beverage, pharmaceutical, transportation & logistics

- Long service intervals for optimal productivity

- Repetitive movements, requiring accurate, consistent positioning

- Broad temperatures (-40 °F to >180 °F)

- Exposure to water, dust, sand, fuels, oils, and other media

- May be subject to FDA compatibility requirements

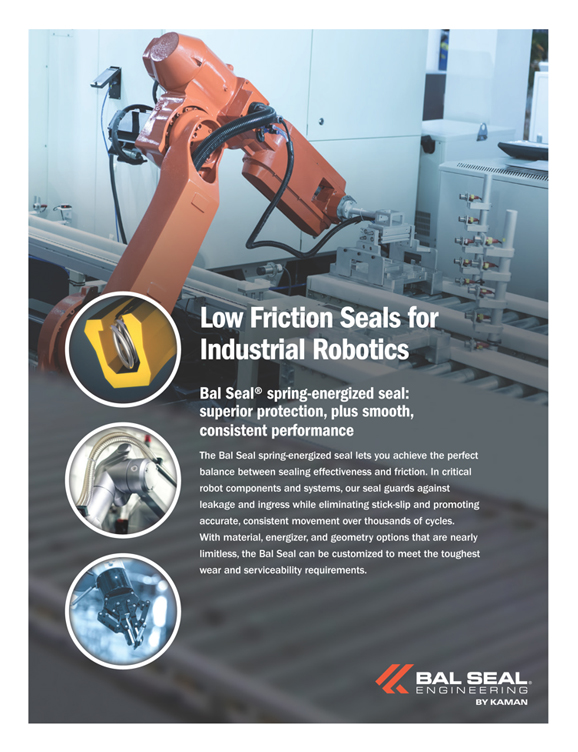

In robot arm joints, end effectors, actuators, and motors, no other seal can match the superior protection against leakage and contamination and low friction performance of the Bal Seal®. With material, energizer, and geometry options that are nearly limitless, the Bal Seal can be customized to meet the toughest wear and serviceability requirements.

A Robotic Sealing Resource

We created this quick-reference guide to help you avoid some common robotic sealing pitfalls, and learn more about the benefits of using Bal Seal spring-energized seals. Download it today, and keep it handy as you begin working on your next great robot design.

Quick-Reference Guide – Seals for Industrial Robotics

Need some sealing help? Click here to get connected with an expert.